SITE MAP

Close

Business COMPANY PORTFOLIO

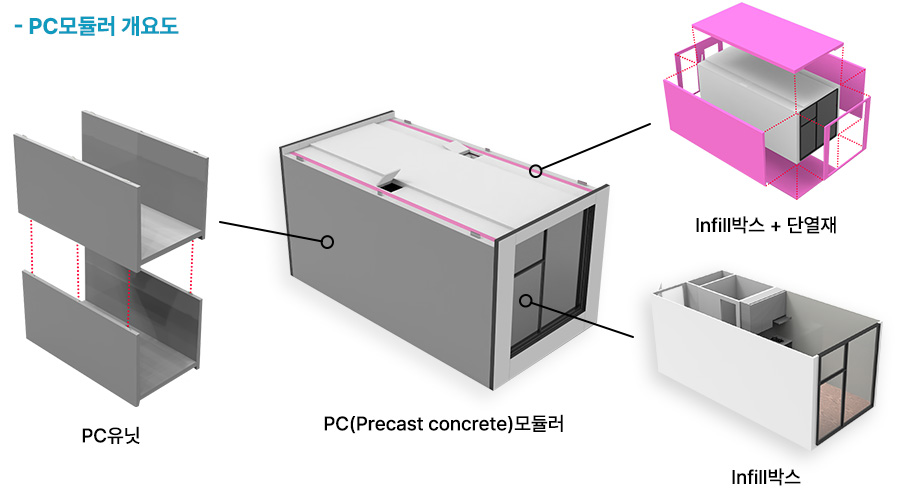

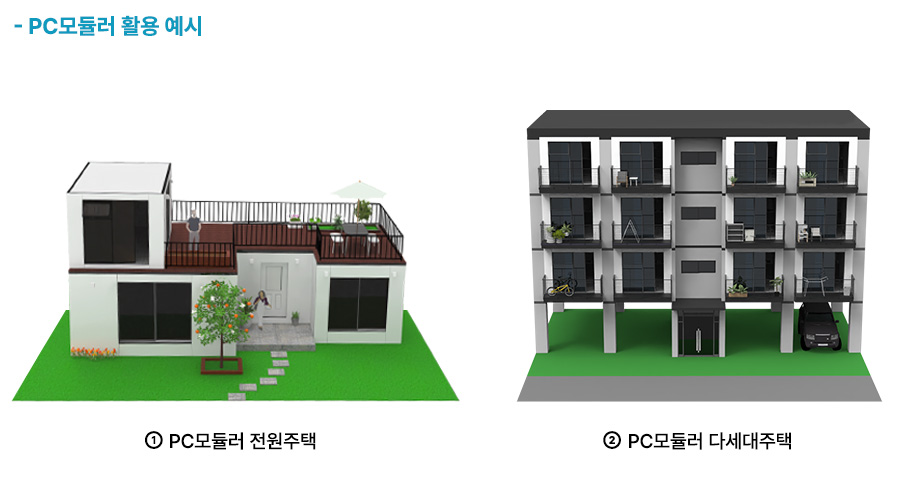

PC Modular

PC Modular Technology Using 3D InfillModular house

Unlike existing housing construction method that most of the processes are carried out on site, Like automobile assembled in a factory, cubes that consists modular house with various of interior materials, mechanical equipment and electrical wiring are prefabricated in a factory. After prefabrication, They will be transported to construction site and will be assembled as a modular house.

Construction method overview

In the case of domestic steel modular houses, the construction cost is about 130-150% higher than that of existing apartment houses, and the prefab ratio is only 50%, so the expansion of supply was limited because the advantages of modular were not utilized.

Accordingly, through a joint research with Korea Institute of Construction TechnologyThe company has a concrete PC unit that is economical, durable and fireproof for the exterior structure, and a 3D infill box is applied for the interior finish. Combing those two technpologies, The company has developed the technology which satisfy botheconomical and constructability.

PC modular assembly flow chart

Minimization of process and preservation of on-site environment through PC modular technology

ⓒKorea Institute of Construction Technology

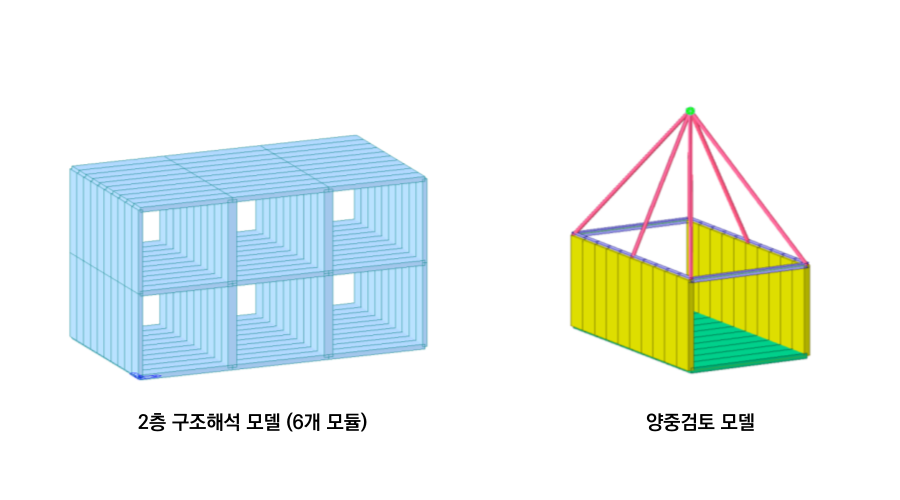

PC module structure design

It complies with the design standards according to the building structure standards announced by the Ministry of Land, Infrastructure and Transport

Reinforced concrete design basis

- Building structure standard announced by the Ministry of Land, Infrastructure and Transport (KDS 41 17)

- Basic Structure Design Standard (2016, Korean Geotechnical Society)

Load design basis

- Building structure standard notified by the Ministry of Land, Infrastructure and Transport (KDS 41 17)

PC module junction design (outer module junction)

- Vertical connection using bolts (16 joint bolts)

PC module junction design (central module junction)

- Use of plate pallet with 15mm horizontal joint

ⓒKorea Institute of Construction Technology

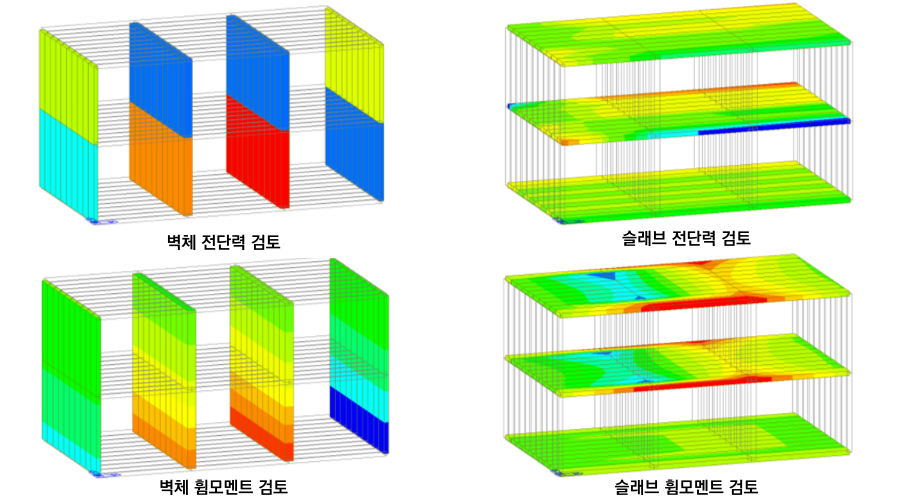

Structural safety

Satisfying the first grade seismic resistance of the interfloor displacement ratio due to the member force and seismic load due to shear and bending

Software Used

- Structural analysis: MIDAS GENw

- Members Design: MIDAS SDS, Deisign+, Best Pro

Structural stability review when lifting

- There is no problem with the stability of the PC module even when connecting 6 or 4 lifting cables (lifting using a balanced beam)

- Satisfying the strength ratio of members including vertical deflection

ⓒKorea Institute of Construction Technology

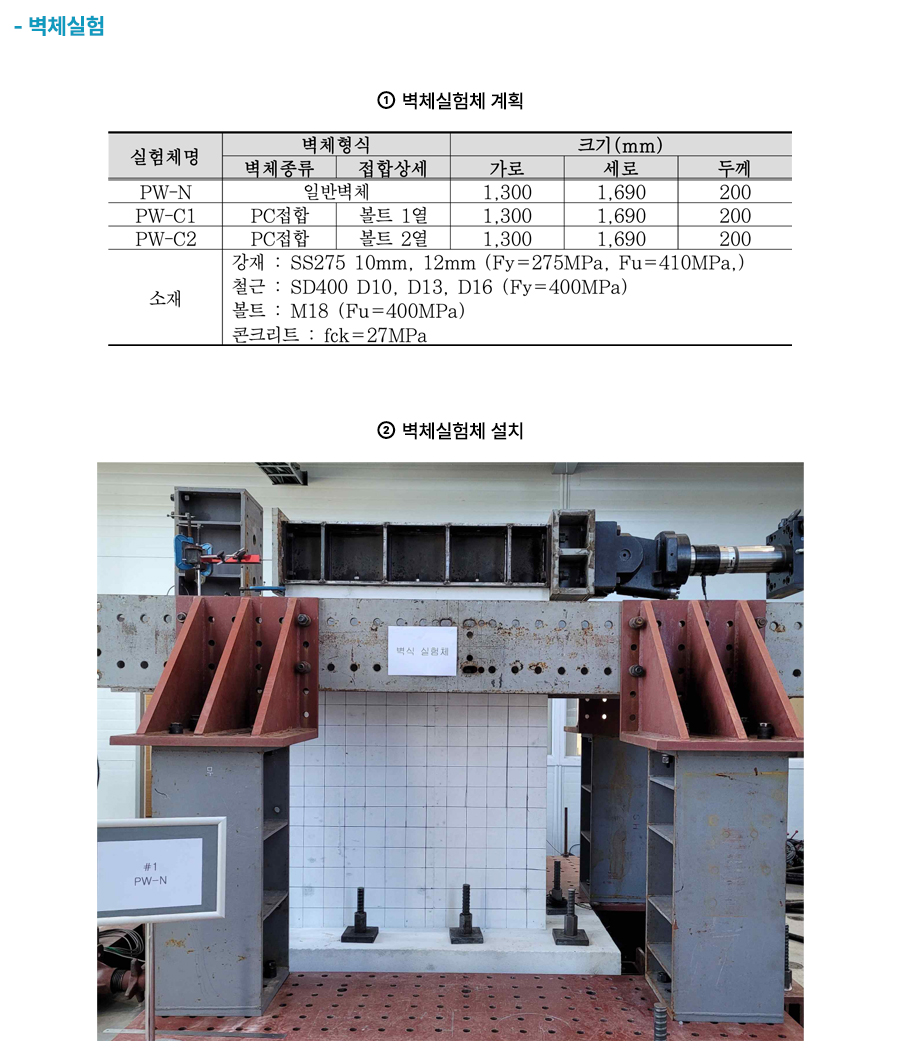

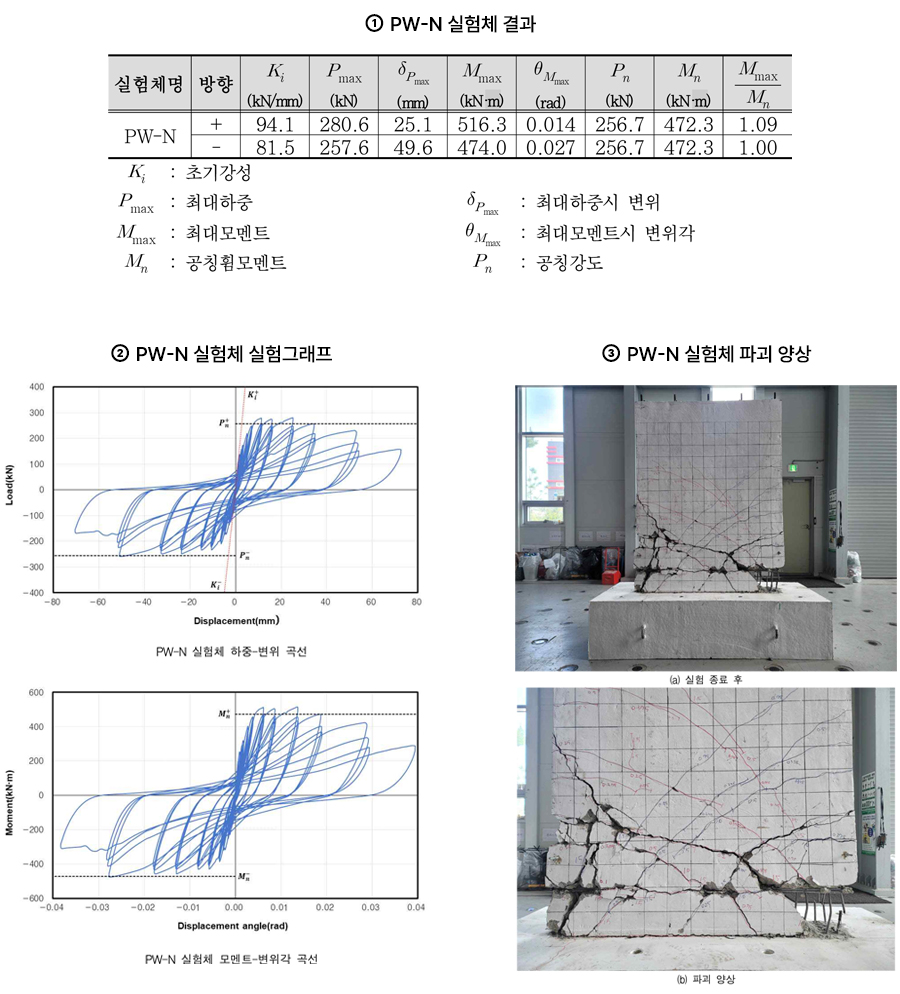

Building structure experiment

In order to evaluate the structural performance of the PC module joint, test subjects(walls) are manufactured and Repeated load test is conducted on a total of three walls.

Through SIM modular structural analysis, each members' displacement and deflection for required loads, wind loads, design loads and earthquake loads were reviewed. As a result, the Proto-type was considered safe.

By examining the load acting on each joint, it was found that there was no problem in the amount of steel in the joint, shear force, safety of bolts and plate safety.

Through SIM modular structural analysis, each members' displacement and deflection for required loads, wind loads, design loads and earthquake loads were reviewed. As a result, the Proto-type was considered safe.

By examining the load acting on each joint, it was found that there was no problem in the amount of steel in the joint, shear force, safety of bolts and plate safety.

ⓒKorea Institute of Construction Technology

ⓒKorea Institute of Construction Technology

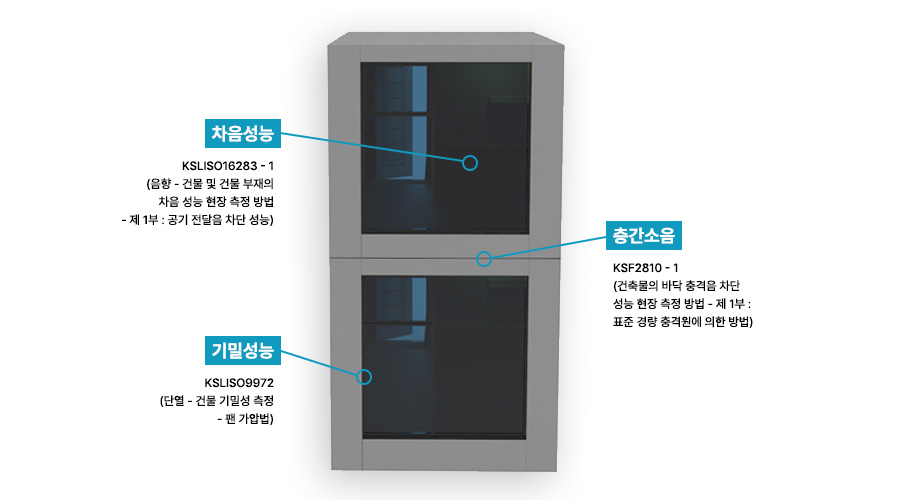

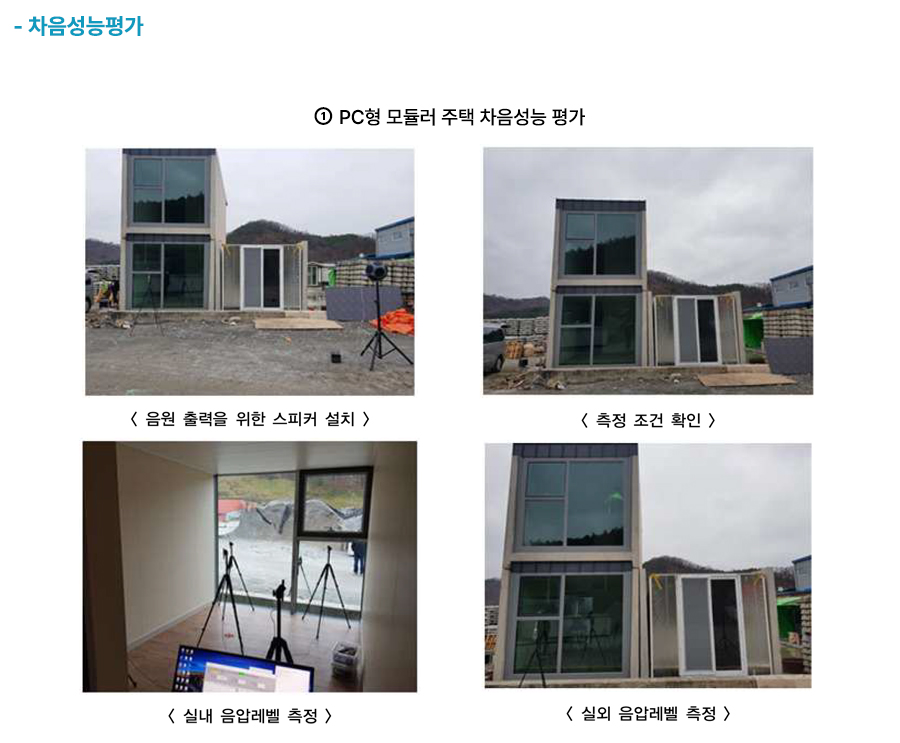

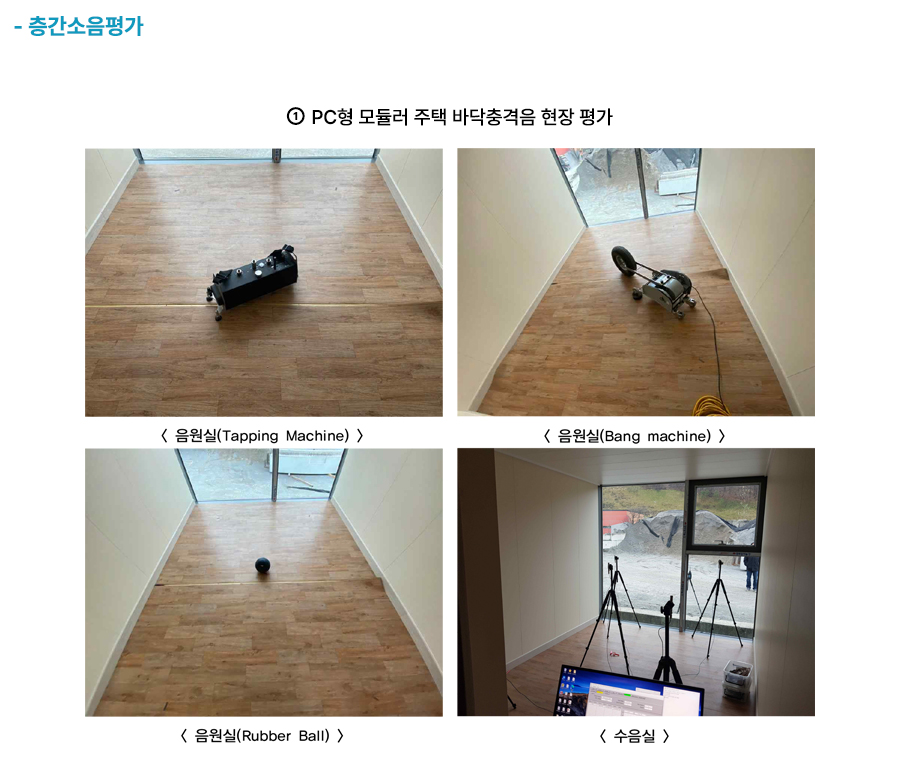

Field performance evaluation

PC Modular Building meets KS standards for sound insulation performance, Airtight performance,Floor noise in field performance evaluation conducted by KCL.

ⓒKorea Institute of Construction Technology

ⓒKorea Institute of Construction Technology

ⓒKorea Institute of Construction Technology

ⓒKorea Institute of Construction Technology

Construction of permitted buildings

A dormitory located in Goesan, Chungcheongbuk-do. This is a one-room style building which is made of an PC modular unit and an infill box with a toilet, insulation and interior materials.

The building is a two-story building and consists of a total of 6 rooms.

The building is a two-story building and consists of a total of 6 rooms.